Refrigerant leak detection and repair

Detection and Repair of Refrigerant Leaks – Guaranteeing Safety, Savings, and Regulatory Compliance

Why is refrigerant leak detection crucial?

If you manage refrigeration or air conditioning systems, the security, efficiency, and longevity of your equipment are of utmost importance. Refrigerant leaks not only lead to increased electricity costs and reduced efficiency but can also cause serious environmental and legal issues. At Maat Engineering Ltd., we offer a professional service for detecting and repairing refrigerant leaks, helping you save money, protect the environment, and comply with European and international regulations.

What are the negative consequences of refrigerant leaks?

❌ Increased energy costs – Insufficient refrigerant levels cause higher electricity consumption as the system operates outside its optimal parameters.

❌ Higher maintenance and repair expenses – Undetected leaks can lead to compressor damage and costly component failures.

❌ High refrigerant costs – Refilling refrigerant is a significant expense that can be avoided with timely leak detection. Specialized refrigerants such as R-404A, R-134a, and R-410A are expensive, and leaks result in constant refilling needs.

❌ Violation of environmental regulations – Refrigerants with high global warming potential (GWP) are strictly regulated by EU Regulation No. 517/2014, F-Gas (1st Category), and EPA 608 Universal. Non-compliance can lead to severe penalties.

❌ Environmental hazard – The release of hydrofluorocarbons (HFCs) into the atmosphere contributes to global warming and depletes the ozone layer. Some refrigerants have thousands of times the climate impact of carbon dioxide (CO₂).

❌ Health risks – Some refrigerants pose health risks when inhaled in high concentrations or over prolonged exposure in enclosed spaces.

Areas of application

✔ Industrial refrigeration systems – Food processing, frozen storage, pharmaceutical companies.

✔ Commercial buildings – Hotels, supermarkets, shopping malls, restaurants.

✔ HVAC systems – Office buildings, hospitals, educational institutions.

✔ Transport systems – Refrigerated trucks, ships, and air transport.

✔ Manufacturing plants – Factories, laboratories, specialized industries.

✔ Marine industry – Commercial and passenger vessels, container ships, fishing boats, and yachts. Marine refrigeration and HVAC systems operate under extreme conditions, and leaks can lead to high costs and serious technical failures while at sea.

How we work?

Our leak detection and diagnostic service utilizes the most advanced technologies, ensuring high precision:

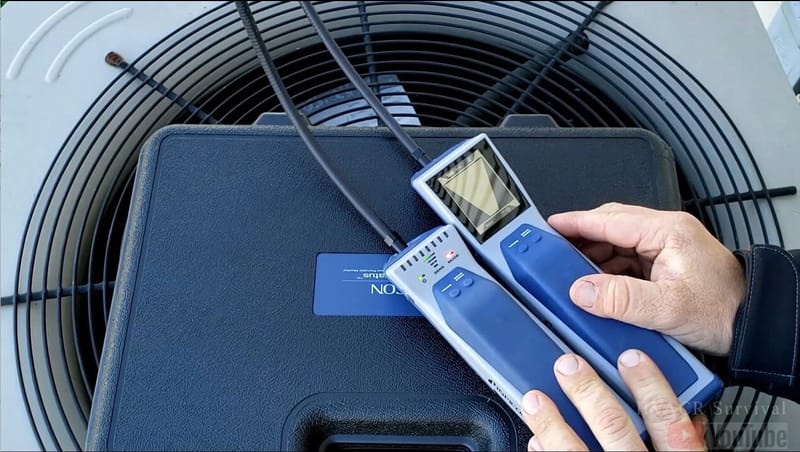

✔ Electronic leak detectors – Detect even minimal concentrations of refrigerant.

✔ UV dyes and UV lamps – Allow for visual detection of leaks.

✔ Thermographic cameras – Identify temperature anomalies caused by refrigerant loss.

✔ High-pressure nitrogen testing – Checks the system’s hermetic integrity.

What are the benefits for You?

✔ Reduced operational costs – A well-maintained system consumes less energy.

✔ Extended equipment lifespan – Prevents costly repairs and component replacements.

✔ Environmental responsibility – Reduces your carbon footprint and contributes to environmental protection.

✔ Regulatory compliance – Avoids fines and legal consequences.

✔ Increased safety – Reduces risks associated with toxic or flammable refrigerants.

Why choose Maat Engineering Ltd?

✔ Years of experience in HVAC and refrigeration systems.

✔ Use of the latest leak detection technologies.

✔ Fast response and professional service.

✔ Complete documentation and compliance reports.

✔ Competitive pricing and customized solutions.

Don't let a small leak turn into a big problem! Contact us today to ensure the reliable and efficient operation of your refrigeration and HVAC systems!

Address: Varna, Student Street No. 4

Phone: +359 890 33 99 33

Email: info@maatengineering.com

Web: www.MaatEngineering.com

Maat Engineering Ltd. – "We Work with Love and Truth."